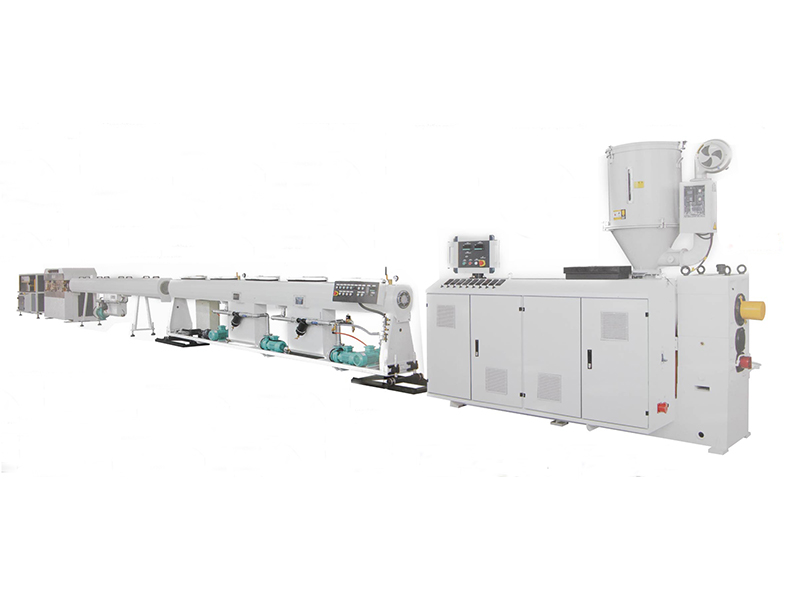

Wholesale China High Speed Pe Pipe Extrusion Line System Suppliers Factories - PP PE PVC single wall corrugated pipe extrusion line – Qiangsheng Plastic

Wholesale China High Speed Pe Pipe Extrusion Line System Suppliers Factories - PP PE PVC single wall corrugated pipe extrusion line – Qiangsheng Plastic Detail:

Application

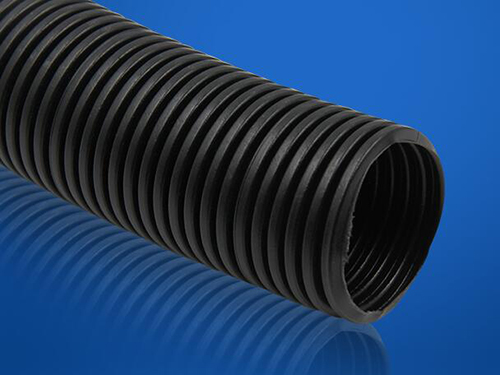

Plastic single wall corrugated pipes have features of high temperature resistance, corrosion and abrasion resiatance,high intensity and good flexibility,etc.they are widely used in fields of auto wire harness, electric thread-passing pipes,circuit of machine tool,protective pipes of lamps and lantern wires,tubes of air conditioner and washing machine,etc. Applications:plastic single wall corrugated pipe making machine can produce electrical thread-passing pipes,circuit of machine tool,protective pipe of lamps,water pipes in conditioner,washing machine, bathroom, etc.

Features

1.Extruder: high efficient screw, hard gear surface gearbox, uniformed raw material heating, good plasticization, high extrusion speed.

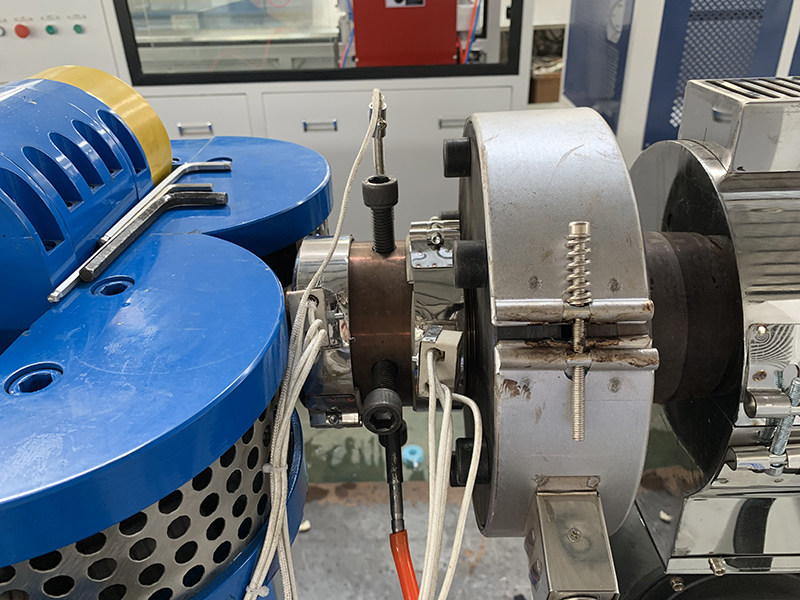

2.Corrugation forming machine: closed structure, module link in the overall closure base does round-trip running in the running tunnels.

3.Forming modules: it is made of hard steel, dealed with a rigorous use of CNC finishing materials produced to ensure the hardness and precision of the molding modules. These modules are easy and convenient to change

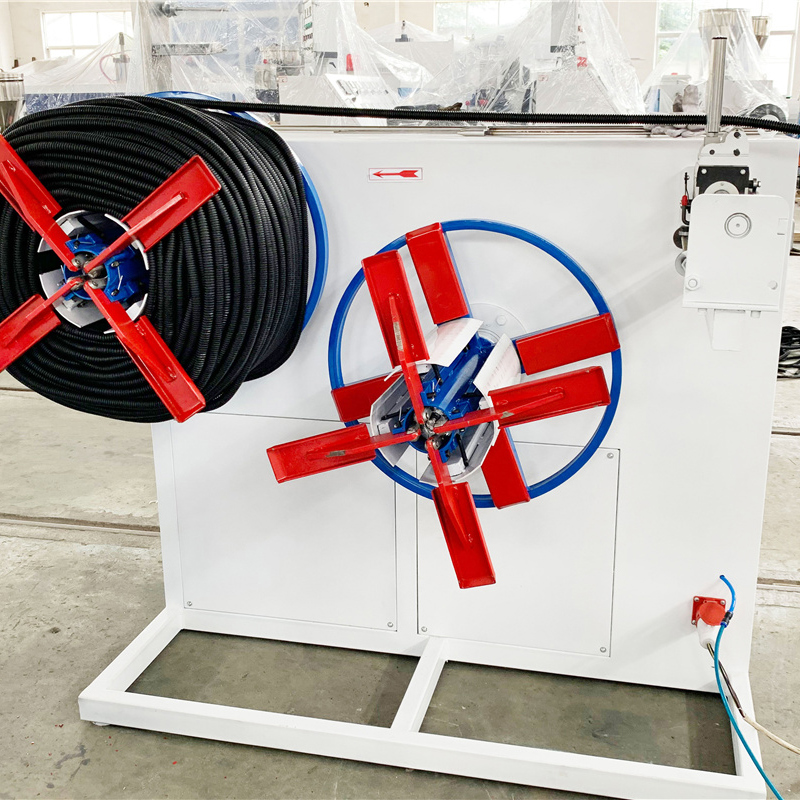

4.Coiler :Single position or double position with torque motor.

5.Electrical parts: ABB inverter, Schneider contactor, RKC thermo controllers etc.

Product Paramenters

|

Corrugated Pipe Diameter |

4.5-9 mm |

9-32mm |

16-50 mm |

|

Main Machine Model |

SJ-30 |

SJ-35 |

SJ-45 |

|

Screw L/D |

30:1 |

30:1 |

30:1 |

|

Production Capacity |

8 kg/h |

15 kg/h |

25 kg/h |

|

Main Motor |

5.5 kw |

7.5 kw |

15 kw |

|

Pair of Modules |

42 |

Depends |

Depends |

|

Production Speed |

6-10 m/min |

8-12 m/min |

8-12 m/min |

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater quality, lessen processing costs, price ranges are much more reasonable, won the new and outdated shoppers the support and affirmation for Wholesale China High Speed Pe Pipe Extrusion Line System Suppliers Factories - PP PE PVC single wall corrugated pipe extrusion line – Qiangsheng Plastic , The product will supply to all over the world, such as: Switzerland, Cyprus, Montreal, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ‘customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.